A guide to custom personality jewelry

Why custom personalized jewelry

The finished jewelry is the designer's professional understanding of jewelry, and aesthetic understanding in the style, so the jewelry itself reflects the professional and aesthetic, as for the meaning, for the finished product is a luxury. Custom jewelry, on the other hand, gives the definition of the meaning of jewelry to the customer, by allowing the customer to choose their own metal, change the gemstone, change the hand size, engraving, and even relay their own inspiration to the designer, to DIY a piece of their own jewelry, the process itself is to allow the customer to set the "meaning" of jewelry. With the development of the Internet and the convenience of logistics and express delivery, more and more people are shopping online for all kinds of goods and services. In China, in order to meet the needs of foreign customers, the services offered are becoming more and more detailed, and the rise of personalized one-piece jewelry customization has also emerged. So what do you need to pay attention to when customizing jewelry?

To know your jewelry manufacturing process

When working with a factory, the main things you need to communicate are the modification of the design, the imposition of the production process, the control of materials, and time costs. This requires you to be familiar with the jewelry production process, the product process, the cost of gold and diamonds, and the design requirements can be clearly and accurately grasped and expressed. These are clear and explicit, and the obstacles to communication with the factory will be greatly reduced.

Each piece of jewelry is infused with soul by the designer and the maker, and it takes a very complicated process of steps to create it. Here we will introduce you to the whole process of a piece of jewelry from design to finished product.

1、Define your customization requirements, stone size, and quality, metal material, style, ring hand size, necklace and bracelet size, engraving, etc.

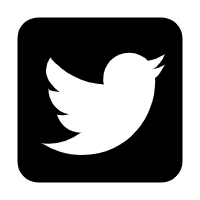

2、Design and draw CAD drawings according to customer requirements.

3、Mold Making: According to the design drawings or physical samples and the starting requirements, use wax blanks or silver materials to make wax molds and silver molds.

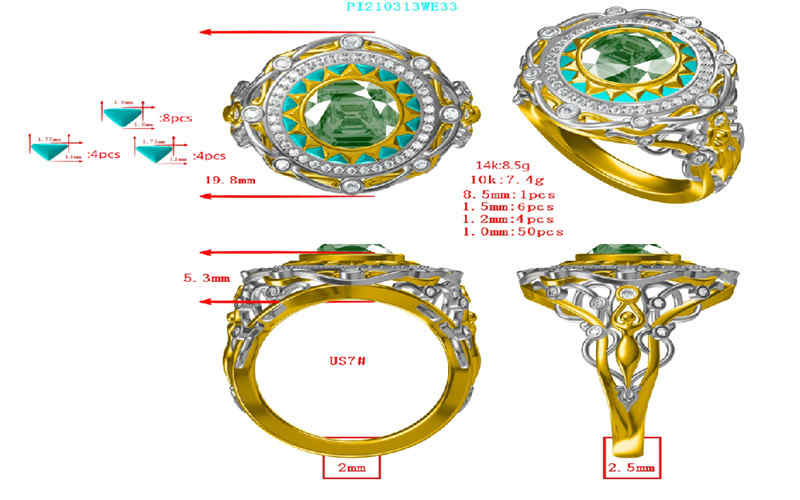

4、Rubber mold: According to the style, size, and thickness of the silver mold, first fill the gaps of the silver mold with the inlay position and the accompanying stone position with a broken rubber strip, and then use 4-6 pieces of raw rubber to seal the silver mold. and then put it into the mold frame and press it at high temperature with a pressing machine. After about half an hour, the raw rubber compressed the silver mold. After opening the rubber and taking out the silver mold, The rubber sheet is hollow to form a rubber mold.

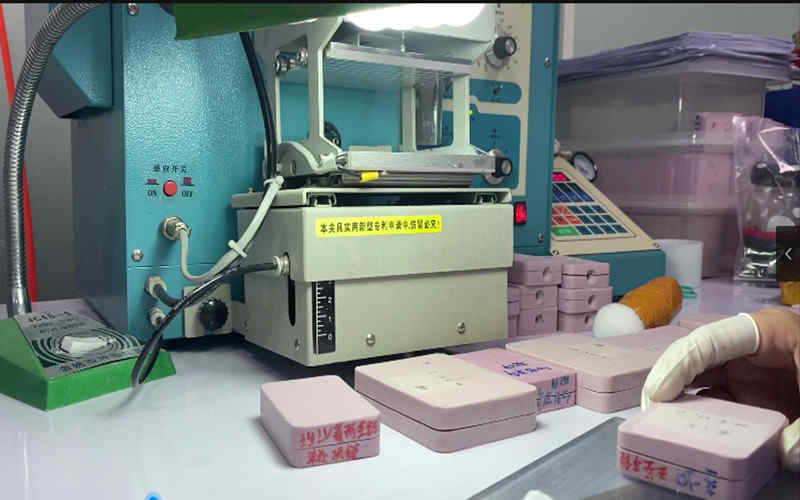

5、Wax/Wax Tree: Pour the cooked wax into the wax injection machine, and use the wax injection machine to inject the wax into the rubber mold along with the water port clamp position of the rubber mold, and then open the rubber mold and take out the wax mold after the wax has solidified. The wax tree is made in a certain order, using a soldering iron in the direction of the circumference of a wax stick in layers, the final shape of the wax tree resembles a tree and then the wax tree will be filled with plaster and other processes.

6、Casting: Sort the wax molds and place them in a steel container. After the plaster slurry has hardened, the steel container is placed in the wax steamer and the wax is continuously heated up and lost. When all the wax has evaporated. The gold liquid is injected into the plaster using an inversion molding machine. The metal model of the jewelry is then formed.

7、Assembly/ Grinding: The components of the jewelry are soldered together and the rough jewelry is reshaped into a semi-finished product with beautiful lines, clear angles, and well-proportioned shapes

8、K-gold color treatment: the metal jewelry after the execution of the mold to remove the dirt and enhance the luster of the treatment (the use of some chemical materials such as potassium cyanide corrosion effect, so that the surface of the empty gold tray to remove the dirt material), so that the metal jewelry pieces in the process of execution of the mold can not deal with defects, in the process of color bombing to remove the metal jewelry pieces to produce the original metal luster.

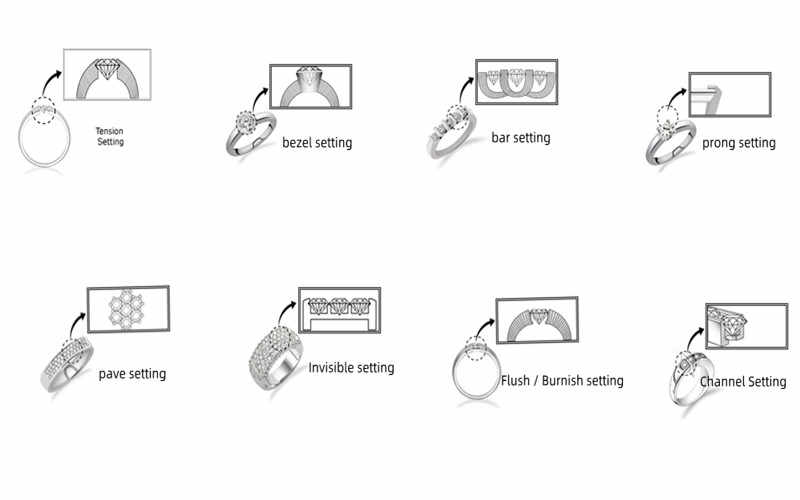

9、Stone Setting: Before setting the stone, the stone setting location must be sanded and polished, while checking for rotten gold or sand holes. The diamonds (or other stones) are fixed to the gold brackets in different settings: claw setting, Nail insertion, channel setting, card setting, bezel setting, Micro insert, Circling setting, cluster setting, Invisible setting, etc.

10、Polishing: According to the polishing requirements of different styles and different positions, we use the polishing machine, flying disc machine, hanging machine and other machines and corresponding gauze wheel and polishing wax to polish the surface of the goods so that the surface of gold jewelry is smooth and bright.

11、Jewelry Finishing: matte finishing/ Sandblasting/ hammered finishing/polished,shiny/satin/brushed/wirebrushed/wired/diamond cut/florentine/rippled

12、Cleaning/Gold Electroplating: The jewelry will be cleaned by an ultrasonic cleaning machine after grinding and polishing. The main function of electroplating is to make the workpiece more stable and brighter by plating a layer of electroplating on the exterior. It makes the jewelry wear-resistant and long-lasting, has good corrosion resistance, and has long-term color so that the platinum jewelry is more crystal, gold jewelry more bright

13、Comprehensive quality checks on jewelry according to product quality inspection standards.

Throughout the process, the client is mainly involved in collecting Jewelry Ideas and CAD Design, finding inspirational photos, or sketching out what you want to order. Be as specific as possible and use as few words as possible. If you don't need a complete replica of an existing design, circle the parts of each image that will be combined. Find photos that show the design from multiple angles, not just the front view. Define your customization requirements, stone size, and quality, metal material, style, ring hand size, necklace and bracelet size, engraving, etc. The jewelry designer will draw a CAD design according to the customer's needs, and the customer can confirm that the CAD image is the result he or she wants and that the jewelry made from the CAD design will have very little error between the actual piece and the CAD.

Where to find custom jewelry manufacturers in China

You can find a lot of manufacturers on Google, Alibaba, 2c platforms such as AliExpress, Amazon, Facebook, and Instagram, and so on.

From the industry's regional competition pattern perspective, most of the jewelry processing enterprises in mainland China are located in Guangdong, Shandong, Shanghai, Fujian, and Zhejiang. Guangdong is the country's main jewelry production base, while Shenzhen and Guangzhou is the main boutique jewelry processing center, the industry chain is relatively mature and complete, and the jewelry inlay processing production in Guangzhou Panyu and Shenzhen Shuiba gold, K gold processing production as a representative, Guangzhou Panyu jewelry: the process has fine work to do the goods, many crafts are inherited from the Hong Kong side of the experienced master plate maker, Panyu jewelry Whether product quality or style design is in line with the international market, with obvious product advantages. Account for 30% of the global market share. Shenzhen jewelry: Shenzhen jewelry processing gold, K gold, diamonds, gemstones inlay is the main, the process of higher precision, the price is also more expensive. After several years of development, jewelry base low-end processing and manufacturing links have gradually moved out, the industry chain shows a trend of concentration to the high-end industry chain such as R & D design, display, and trading. but not every manufacturer is suitable, so how should we choose the right high-quality manufacturers in China?

How to choose a high quality manufacturers in China?

-

1, large jewelry factories have long-term stable customers, and the number of orders for processing and production is relatively large, this type of factory basically does not need to consider, because there is no volume, and basically will not talk to you.

-

2, the factory area of about several hundred square meters, the number of employees about 20-50 people factory, the number of such factories is relatively large, need to be screened. Mainly look at the first look at the boss's attitude towards product quality, as well as the attitude towards customer service. The second look at the product, the first communication to understand the manufacturer's process, and then through the purchase of some samples, and then from the samples to see the manufacturer's process and quality, to judge the craft good or bad. Because some jewelry just from the appearance of the process is difficult to judge, so for some samples, it is best to wear them for a period of time, so that you can basically filter out some of their more satisfied with the manufacturers.

-

3, to their more satisfied manufacturers, you can try to sample with them, through the process of sampling, you can feel the degree of cooperation with the factory, as well as to verify the quality of the factory's services and products.

-

4、When you only want to customize a piece or do not want to sample, you can look at other customers' comments (Reddit/price scope/wedding bee) on the website of the intended manufacturer or various forum platforms to determine whether it is suitable.

-

5, only the above is not enough, after all, as a downstream, to sincerely serve the customer, but also consider the after-sales problem, so also to understand how the factory after-sales, whether the proportion can be returned to the factory repair, whether the plating again, its related costs and so on.

-

Finished Jewelry production, the next step is the logistics, for precious metal jewelry, each country's import tariffs are different, but the same is tariff rate is not low, you can communicate with the merchant to declare the name and amount, which can reasonably reduce tariffs.

Back to Top

Back to Top

Email Us

Email Us +8613481477286

+8613481477286

.png)